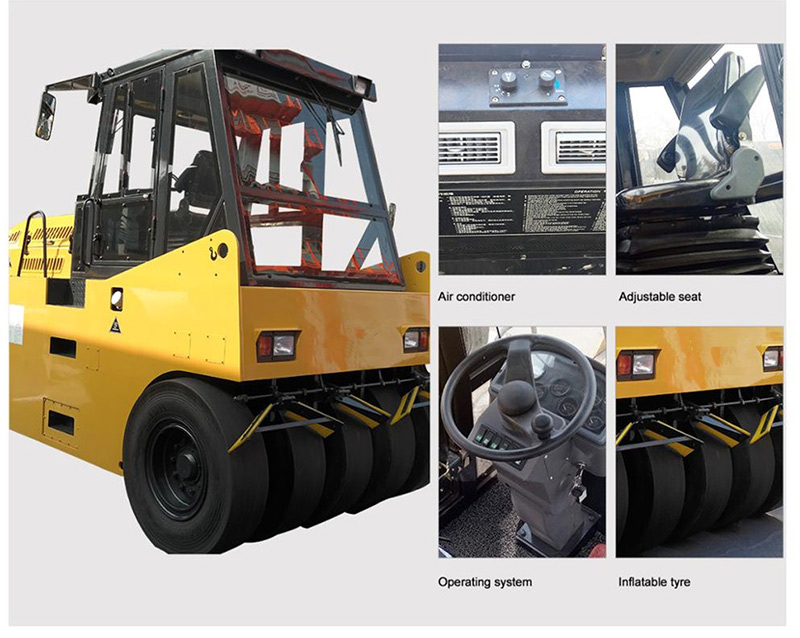

The pneumatic roller is a kind of machine that uses multiple pneumatic tires to compact the road. Tire rollers use pneumatic tires, usually equipped with 3 to 5 front wheels and 4 to 6 rear wheels. If you change the inflation pressure, the ground pressure can be changed, and the pressure adjustment range is 0.11~1.05 MPa. It adopts a mechanical transmission system, single-shaft or shaft drive, and three-point support with a wide-base tire articulated frame structure. The compaction process has the effect of rubbing so that the particles of the compacted layer will not be destroyed but embedded in each other, and the particles will be uniform and dense.

InquiryLTP1016/1TP1826/LTP2030 low gravitational center designed for safe and comfortable operation;

LTP1016/1TP1826/LTP2030 adopted 4BT Cummins engine, is suitable to all environments.

Three forward speed and two backward changes, a reinforced plastic spraying box, and a multi-layer water filter ensure the stability of the system.

Power strong, LTP1016/1TP1826/LTP2030 adopted 4BT Cummins engine, is suitable to all environments.

LTP1016/LTP1826/LTP2030 Mechanical drive pneumatic tyre roller main technical parameters

LTP1016/LTP1826/LTP2030 Mechanical drive pneumatic tyre roller main technical parametersModel LTP1016 LTP1826 LTP2030

Operating mass(unballast/ballast) kg 10000/16000 18000/26000 20000/30000

Max.travel speed Km/h 14.7 20.64 20.64

Tyre quantity(front +back ) / 4+5 5+6 5+6

Min. Turning radius mm 7500 8000 8000

The presses width mm 2280 2790 2790

Grade ability % 30 30 30

wheelbase mm 3700 3700 3800

Overall dimension mm 4780*2100*3200 4950*2750*3240 4950*2750*3240

Diesel power kw 75 125 125

Diesel model Cummins 4BT3.9 Cummins 4BTA5.9 Cummins 4BTA5.9

The tire roller series relies on its weight to compact viscous and non-cohesive materials in construction and road engineering such as asphalt concrete, gravel mixture, various stabilized soils, and roller-compacted cement concrete (PCC materials), etc., especially suitable for high-grade Road surface treatment.